NDT Inspection

Ultrasonic Testing (UT)

In ultrasonic testing (UT), very short ultrasonic pulse waves with center frequencies ranging from 0.1-15 MHz and occasionally up to 50 MHz are launched into materials to detect internal flaws or to characterize materials. The technique is also commonly used to determine the thickness of the test object. For example, to monitor pipe work corrosion.

Ultrasonic testing is often performed on steel and other metals and alloys, though it can also be used on concrete, wood, and composites, albeit with less resolution.

Visual Inspection (VT)

- The welding inspector must observe several individual stages of the fabrication process.

- The responsibilities of the welding inspector are placed into categories by when they take place.

- The responsibilities take place before, during, and after welding is performed.

Magnetic Particle Testing (MT)

- Is a nondestructive testing (NDT) process for detecting surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The process induces a magnetic field into the part. The piece can be magnetized by direct or indirect magnetization.

- The presence of a surface or subsurface discontinuity in the material allows the magnetic flux to leak. Particles are added and will be attracted to indication or flaw.

Liquid Penetrant Testing (PT)

- Locate surface-breaking defects in all non-porous materials (metals, plastics, or ceramics). The penetrant may be applied to all non-ferrous materials and ferrous materials, although for ferrous components magnetic-particle inspection is often used instead for its subsurface detection capability. LPI is used to detect casting, forging, and welding surface defects such as hairline cracks, surface porosity leaks in new products, and fatigue cracks on in-service components.

Radiography Testing (RT)

- Radiography (X-ray) is one of the most important, versatile, and widely accepted of all nondestructive examination methods. X-ray is used to determine the internal soundness of welds. The term X-ray quality is widely used to indicate high quality in welds, which arises from this inspection method. The X-ray produces photographic records of transmitted radiant energy.

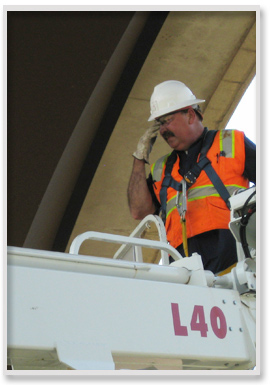

Certified Welding Inspector/ultrasonic technician in man lift preparing to enter a fracture-critical bridge member to perform ultrasonic testing on bridge pins.

Technician performing calibration on ultrasonic instrument and preparing to test a field weld on a commercial building.